Fiberglass grating fasteners connect and fix grating plates to support structures. They are important accessories. Their use can avoid the inconvenience of disassembly and assembly. It can also prevent damage to the platform from welding fixation methods. This article will explain, in detail, fiberglass grating fasteners. It will cover their function, installation, and where to buy them. It aims to help you use them better. This will improve construction efficiency and platform safety.

fiberglass grating installation clips

Fiberglass Grating Fasteners

Detailed Introduction

The fiberglass grating fastener is a special accessory. It fixes fiberglass grating plates to support beams and avoids damaging the plates’ surfaces. It mainly consists of three parts:

The upper clip is firmly attached to the top of the fiberglass grating and serves a fixing function.

Lower clamping device: It is at the bottom of the support beam. It ensures the fiberglass grating is firmly attached to the support structure.

Bolts and nuts: Connect the upper and lower clips, and adjust the fixing strength.

Fiberglass grating fasteners have extensive applications in industrial settings. They are essential for installing fiberglass grating on platforms, stairs, and passages.

Installation Steps

Step 1: Prepare tools and materials

Tools: Wrench, electric drill (if needed for drilling and fixing).

Materials: fiberglass grating fasteners, bolts and fiberglass grating plates.

Step 2: Position the fiberglass grating

Place the fiberglass grating on the support beams. The grating must align with the platform support beams.

Step 3: Install the upper and lower clips

Fix the upper clip to the top of the fiberglass grating, ensuring it fully covers the edge of the grid.

The installer places the lower clasp at the beam’s bottom. Bolts connect it to the upper clasp.

Step 4: Tighten the bolts

Use a wrench to tighten the bolts. Adjust the fasteners. The fiberglass grating must be fixed, with no looseness.

Step 5: Check the installation effect

Check that the fasteners are in the correct position. The fiberglass grating must be stable, with no displacement. Also, recheck the bolts and nuts for reinforcement.

Shopping Guide

Material Selection

Carbon steel: Moderate price, suitable for general industrial environments.

Stainless steel: It resists corrosion. It works in humid, corrosive environments.

2. Specification Matching

Choose the right fastener model. It should match the grid spacing and the grating’s thickness. Common specifications include G355, G323, etc.

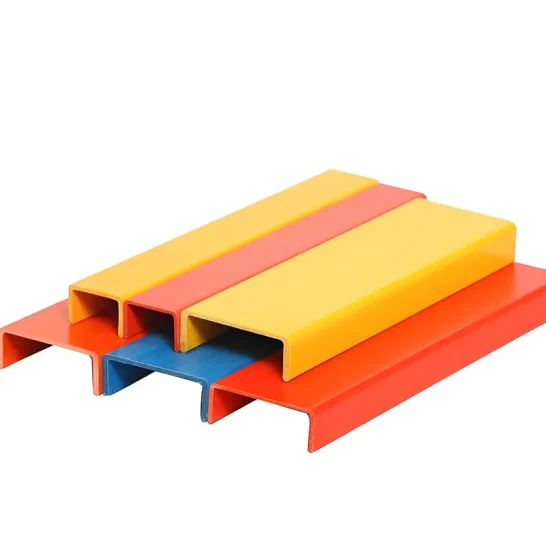

3. Anti-corrosion Treatment

Choose products that have been hot-dip galvanized or powder-coated. These treatments can significantly extend their service life.

4. Load-bearing Capacity

For heavy-load environments, select fixed clips with high-strength load-bearing capacity.

5. Brand and After-sales Service

Focus on well-known brands with quality guarantees. Check if they offer good after-sales service.

Application Advantages

Easy installation: No welding is necessary, which facilitates disassembly, assembly, and movement.

Non-destructive protection: Avoid damaging the fiberglass grating’s coating or galvanized layer during welding.

Strong adaptability: Suitable for fiberglass grating plates of different materials, specifications, and thicknesses.

Improve safety: Use a strong method to fasten the fiberglass grating to the platform. This will reduce accident risks.

Hengshui Hongwo Technology Co., Ltd.

Hengshui Hongwo Technology Co., Ltd.

WeChat

Scan the QR Code with WeChat