What is Molded FRP Grating?

Molded FRP grating is a composite grating product formed through a precision molding process. Fiberglass strands are saturated with resin and placed in a mold, then cured under heat and pressure. The result is a one-piece, integral mesh panel that combines strength, chemical resistance, and slip protection.

Unlike metal gratings, molded FRP grating does not rust, conduct electricity, or require repainting. Its uniform construction provides equal strength in both directions, making it reliable for long-term use in harsh working environments.

Key Features of Molded FRP Grating

Corrosion Resistance – Withstands acids, alkalis, and solvents better than steel or aluminum.

Slip Resistance – Standard grit surface ensures worker safety in wet or oily conditions.

Lightweight but Strong – Easy to handle, install, and cut without heavy equipment.

Non-Conductive & Fire-Retardant – Safer for use in electrical and flammable environments.

Maintenance-Free – Long service life without frequent painting or coating.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Fiberglass Reinforced Plastic (FRP) |

| Manufacturing Process | Molding with thermosetting resin |

| Resin Types Available | Isophthalic, Orthophthalic, Vinyl Ester, Phenolic |

| Panel Thickness | 25 mm, 30 mm, 38 mm (custom on request) |

| Standard Panel Sizes | 1220 × 3660 mm / 1000 × 3000 mm / customized |

| Mesh Pattern | Square mesh, rectangular mesh, mini mesh |

| Surface Options | Gritted, smooth, concave |

| Load Capacity | Up to heavy-duty pedestrian and light vehicular traffic |

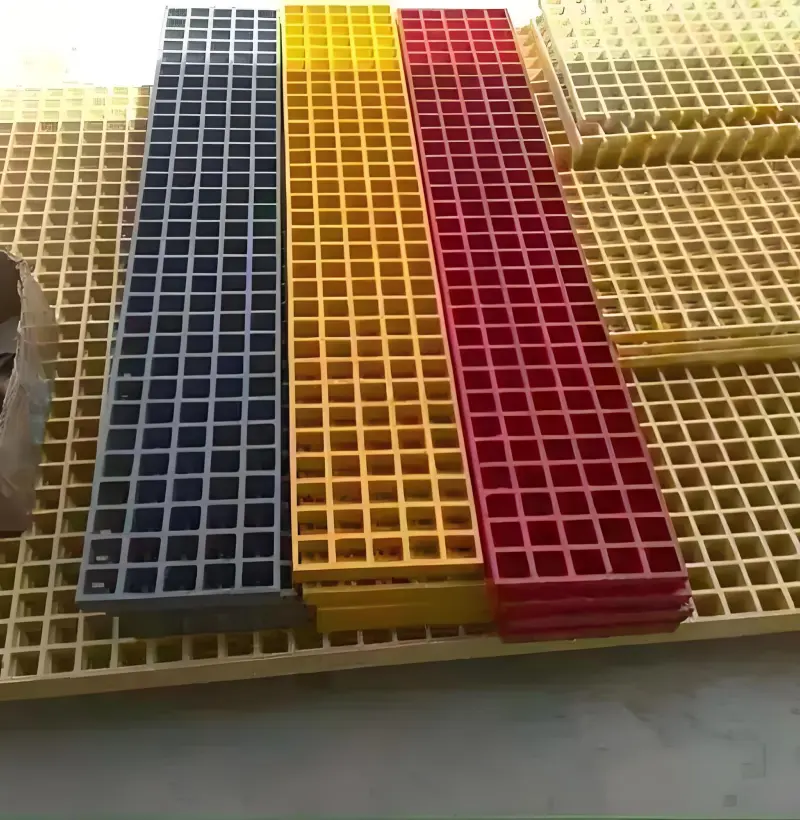

| Color Options | Green, gray, yellow, custom RAL colors |

| Standards | ASTM, ISO, EN compliance available |

Product Data & Technical Documents

Download datasheets, chemical resistance charts, test reports and cutting templates.

Applications of Molded FRP Grating

Industrial Applications

Walkways and platforms in chemical plants

Floor grating in power stations and wastewater treatment facilities

Trench covers in factories and warehouses

Marine & Offshore

Ship decks, docks, and offshore rigs

Corrosion-proof walkways in saltwater environments

Public Infrastructure

Pedestrian bridges and park walkways

Drain covers in municipal projects

Advantages for B2B Buyers

Cost-effective alternative to stainless steel grating

Lightweight panels reduce shipping and installation costs

Available in bulk with OEM customization

Suitable for long-term use in aggressive industrial environments

Frequently Asked Questions (FAQ)

Q1: What is the difference between molded FRP grating and pultruded FRP grating?

A1: Molded grating is produced in a mold, giving it uniform strength in both directions, while pultruded grating has higher glass content and greater load-bearing strength in one direction. Molded grating is more suitable for corrosive and pedestrian-heavy environments.

Q2: Can molded FRP grating be customized in size and color?

A2: Yes, we provide custom cutting services and a wide range of RAL colors to meet project-specific requirements.

Q3: Is molded FRP grating fire-resistant?

A3: Yes, depending on resin selection, molded grating can meet ASTM E-84 and other fire-retardant standards.

Q4: How does molded FRP grating compare in cost to steel grating?

A4: The upfront cost may be slightly higher, but the long-term savings from reduced maintenance, corrosion resistance, and lightweight handling make it more economical.

Q5: Where is molded FRP grating most commonly used?

A5: It is widely used in chemical processing plants, offshore oil rigs, shipyards, wastewater treatment facilities, and infrastructure projects requiring durable, anti-slip flooring.