The Colorful World of Fiberglass Grating: More Varieties Than Ice Cream Flavors!

By Peter Liu, FRP Specialist @GlobalGrate Solutions

Let’s be real – most people think fiberglass grating is just “that plastic stuff that won’t rust.” But what if I told you there are more types than toppings at a frozen yogurt shop? Grab your safety gloves; we’re diving into a maze of resins, weaves, and surfaces that’ll make your next project sparkle.

Molded Grating

- Molded Grating

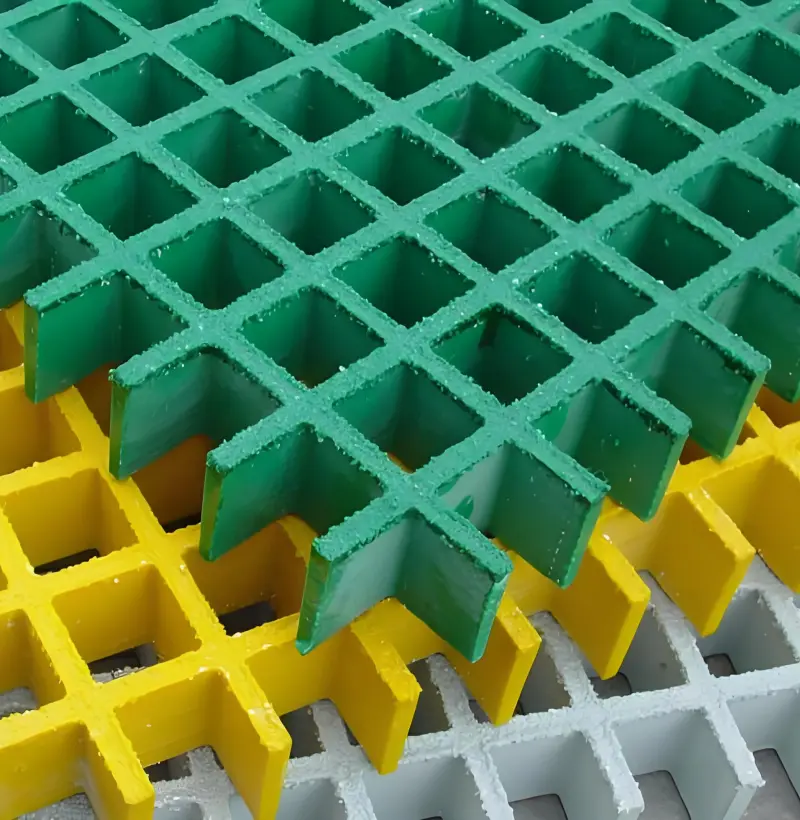

1. The Classic: Molded Grating

Picture a waffle iron making industrial-strength pancakes. Molded grating’s crisscross pattern (typically 38x38mm mesh) has been protecting chemical plants since the 1960s. Its claim to fame? Multi-directional strength perfect for oil refinery walkways where spills and impacts are as common as coffee breaks.

Fun Fact: A Canadian mining site reported 22% fewer slip incidents after switching to molded grating’s textured surface. But beware – its weight (up to 18kg/m²) once made me rethink a rooftop installation during a windy afternoon!

Pultruded Grating

- Pultruded Grating

2. The Athlete: Pultruded Grating

If molded grating is a reliable pickup truck, pultruded is a sports car. With fibers aligned in one direction, it handles bridge deck loads (up to 500 kPa!) like Simone Biles sticks landings. Petrochemical giant Shell saved 14% on offshore platform costs using pultruded’s lightweight corrosion resistance.

But here’s the twist: Its unidirectional strength backfired when a Florida marina used it for curved stair treads. Let’s just say we learned why flexibility matters the hard way.

3. The Firefighter: Phenolic Grating

Meet the grating that laughs at fire. Infused with phenolic resin, it withstands 150°C+ temperatures – a hero in foundries and power plants. A German steel mill reduced annual grating replacements from 3 to 1 after adopting phenolic.

Cost Alert: Prepare for sticker shock – it’s 40% pricier than standard molded. But as my boss always says: “You can’t put a price on not burning down.”

4. The Ninja: Close-Mesh Grating

Tiny 19x19mm openings make this the go-to for food processing plants where cherry pits and chicken bones love to cause trouble. USDA reports show 93% fewer product drop-throughs with close-mesh designs.

Installation Hack: We once used translucent close-mesh in a Singapore aquarium’s walkway – visitors now spot sharks swimming beneath their feet!

5. The Transformer: Grit-Top Surfaces

Not technically a type, but a game-changer. Adding 60-grit silica creates slip resistance rivaling sandpaper. A Dutch bicycle parking garage slashed winter fall injuries by 60% using grit-top panels.

Pro Tip: Avoid this near barefoot areas – ask me about the “tropical resort toe disaster of 2019.”

6. The Heavyweight: Extra-Thick Grating

When standard grating won’t cut it, 50mm-thick monsters step in. They’ve carried mining trucks weighing 12 tons across Australian outback access roads without breaking a sweat.

Sustainability Win: A solar farm project reused thick grating sections as erosion control mats. Genius or crazy? Why not both!

Choosing Your Champion

Still confused? Here’s my cheat sheet:

- Chemicals attacking? → Phenolic

- Budget tight? → Molded

- Need see-through magic? → Transparent resin panels

- Showing off engineering skills? → Hybrid molded-pultruded systems

Hengshui Hongwo Technology Co., Ltd.

Hengshui Hongwo Technology Co., Ltd.

WeChat

Scan the QR Code with WeChat