| Polyester Resin (Molded) | Good general corrosion resistance; cost-efficient | Walkways, platforms in non-severe chemicals | Lower cost; good mechanical performance for light-medium loads | Moderate chemical/temperature limits vs vinyl ester/epoxy |

| Vinyl Ester Resin | Stronger chemical and fatigue resistance | Chemical plants, seawater-exposed platforms | Improved longevity in aggressive environments | Higher material cost than polyester |

| Epoxy / High-Performance Resin | Superior mechanical & thermal performance | Critical high-load zones, specialized applications | High strength, excellent bond with reinforcements | Most expensive; used selectively |

| Smooth / Molded Top | Easy to clean, lower drag | Food, pharmaceutical, clean processing | Hygienic, easy maintenance | Lower slip resistance unless textured finishing |

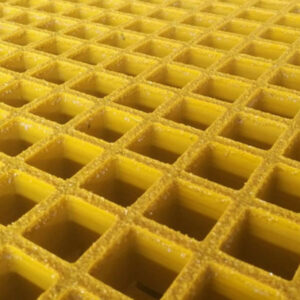

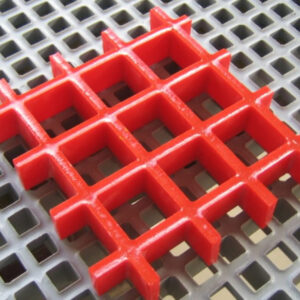

| Gritted / Anti-Slip | High slip-resistance under contamination | Offshore decks, oily/icy zones | Excellent traction, safety | Can wear over long-term and trap debris |

| Conductive / Dissipative Top | ESD safe surface per specification | Hazardous areas, electronics assembly | Controls static; improves safety in classified zones | Usually higher cost; verify conductivity spec |